The Role of FTTH Drop Cables in Modern Fiber Networks

In recent years, the fiber optic cable access market has grown rapidly, becoming a key driver of innovation in optical communications. As FTTH (Fiber to the Home) deployment accelerates, the indoor wiring segment—especially the final drop to the user—has become one of the most technically demanding areas. Conventional indoor cables often fail to meet the bending and tensile strength requirements of today’s FTTH environments, driving the development of more advanced drop cable solutions.

What Is an FTTH Drop Cable?

FTTH represents the most advanced stage in optical access networks. Depending on the location of the Optical Network Unit (ONU), fiber access can be classified as FTTH, FTTB (Fiber to the Building), FTTP (to the Premises), or FTTC (to the Curb). Most of these deployments rely on a PON (Passive Optical Network) structure, where optical splitters distribute signals to multiple endpoints.

In an FTTH setup, fiber optic cables fall into three categories: feeder cables, distribution cables, and drop cables. Among these, the drop cable plays a critical role in connecting the network directly to the end user. This final segment demands high flexibility, durability, and consistent performance. Challenges like higher costs and limited mechanical properties in traditional drop cables have sparked continuous innovation.

Jiqian’s FTTH Drop Cable Solution

At Jiqian Fiber Optic Cable, we specialize in developing and manufacturing high-performance non-armored FTTH drop cables tailored for real-world applications. These cables are designed to deliver reliability, flexibility, and ease of installation in various indoor environments.

Non-Armored FTTH Drop Cables:

Ideal for fixed indoor routing, such as duct installations, wall-mounted wiring, or short-distance connections within residential or commercial buildings. These cables offer excellent bend performance and compatibility with standard connectors, making them a practical choice for modern FTTH deployments.

Structure and Key Features

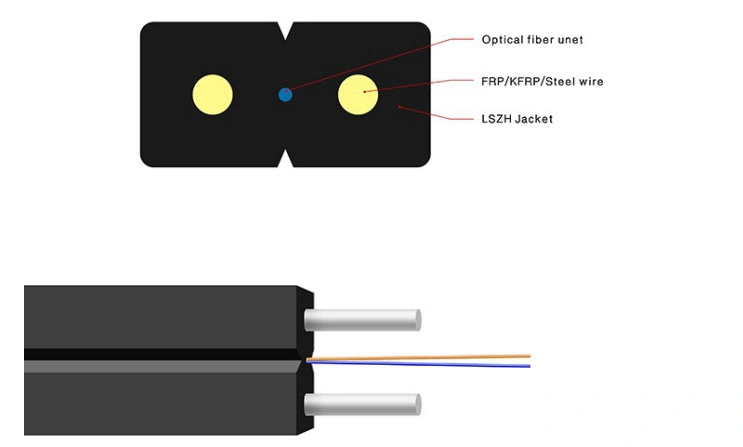

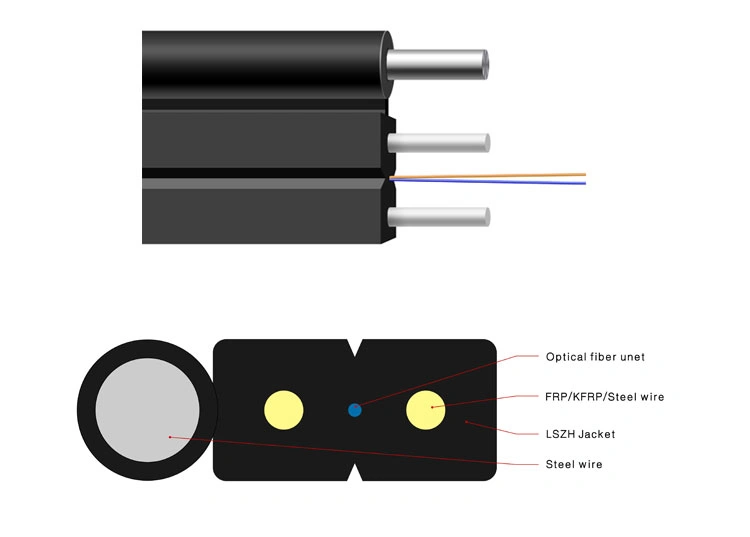

Jiqian’s FTTH drop cables are available in single-core, dual-core, and multi-core configurations (up to 12 cores). They feature a distinctive figure-8 design and include metallic or non-metallic strength members, depending on specific application needs.

- Bend Performance:

We use G.657A2 bend-insensitive fibers, allowing installations with tight 20mm bending radii—ideal for compact home layouts. - Connector Compatibility:

Standard 2.0mm × 3.1mm dimensions make our cables compatible with most pre-terminated and field-installable connectors. - Reinforcement Options:

- Metallic: We use copper-clad steel for better tensile strength and reduced spring-back, ideal for horizontal or vertical runs.

- Non-metallic (FRP): Suitable for fully dielectric applications and safe for use in lightning-prone environments.

Sheath Materials

We offer two sheathing options:

- PVC: Standard, cost-effective, and flexible.

- LSZH (Low Smoke Zero Halogen): Flame-retardant and UV-resistant (especially in black), making it suitable for both indoor and outdoor transitions.

Why Choose Jiqian?

Since 2012, Jiqian Fiber Optic Cable has combined over a decade of technical know-how with a strong commitment to quality. We specialize in designing, producing, and globally supplying fiber optic cables and connectivity solutions. Our FTTH drop cable series reflects our ongoing pursuit of innovation, safety, and installation efficiency in fiber access networks.